Sintered Wire Mesh

Overview

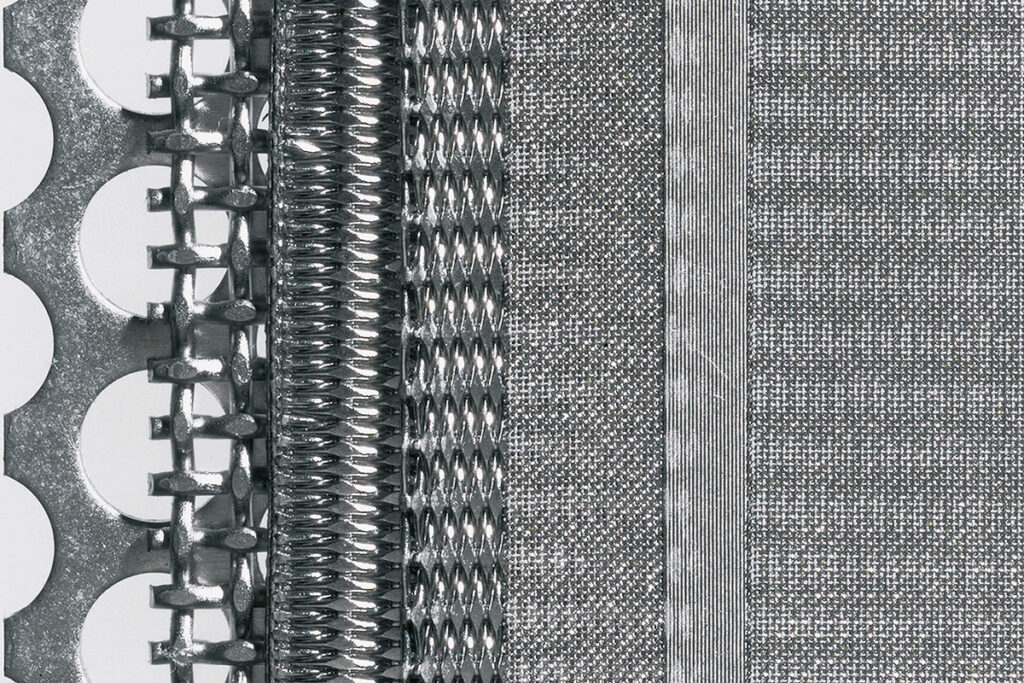

Sintered Wire Mesh is a rigid, multi-layer filtration material manufactured by bonding layers of woven metal mesh through a controlled sintering process. This structure provides excellent mechanical strength, precise filtration accuracy and long service life, even under extreme operating conditions.

At Genius Filters and Systems Pvt. Ltd., our sintered wire mesh is engineered to deliver consistent filtration performance in demanding industrial environments where reliability and precision are critical.

Key features & benefits

High filtration accuracy with uniform pore structure

Excellent mechanical strength and dimensional stability

Low pressure drop with high permeability

Resistant to high temperatures, pressure, and corrosion

Cleanable and reusable for extended service life

Stable performance under fluctuating operating conditions

Applications

Industrial air and liquid filtration systems

Gas turbine and compressor filtration

Hydraulic and lubrication systems

Chemical and petrochemical processing

Power generation and heavy engineering applications

Why choose Genius Sintered Wire Mesh?

Manufactured to stringent quality and performance standards

Available in various micron ratings and layer configurations

Custom sizes and designs for OEM and replacement applications

Proven reliability in harsh and high-load environments

Custom-Engineered Filtration Solutions

We offer tailor-made sintered wire mesh solutions based on filtration efficiency, operating pressure, temperature and application requirements.